Usually ships within 3-5 business days

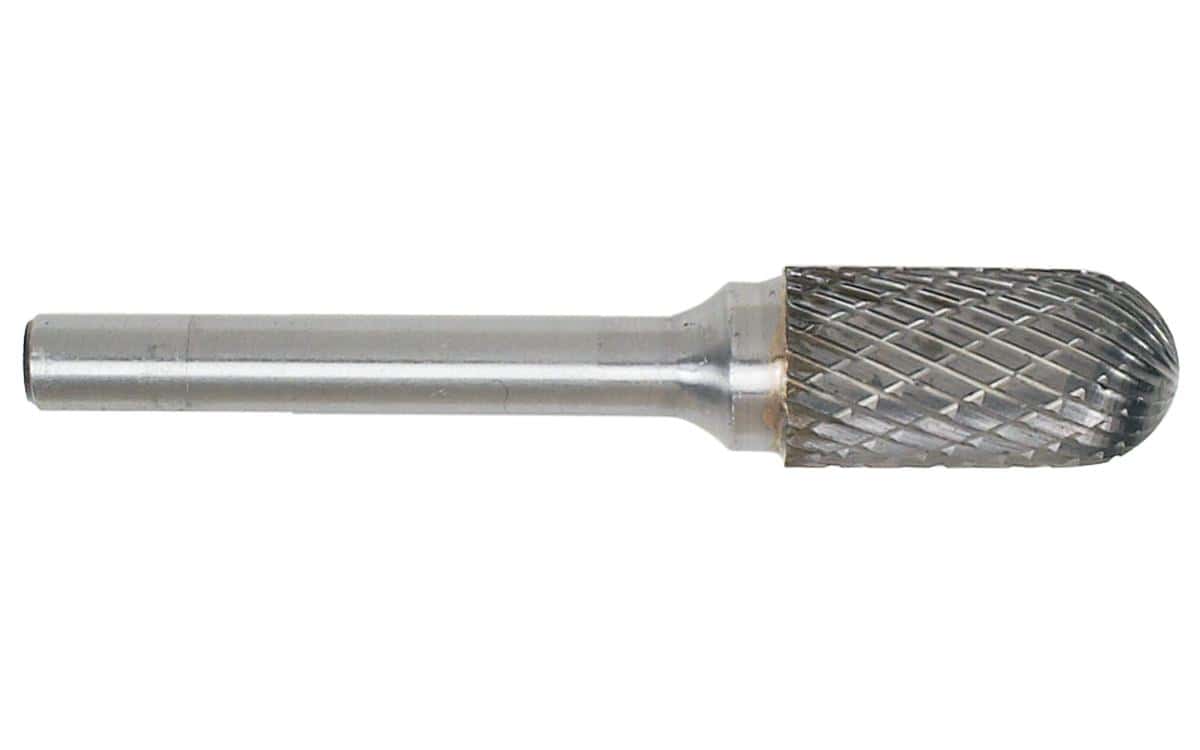

The Walter 01V039 SC-2 Double Cut Carbide Burr represents the pinnacle of material removal technology for industrial professionals. Manufactured from the highest grade tungsten carbide, this rotary file is designed to withstand the rigorous demands of heavy-duty metalworking environments. The SC-2 shape—cylindrical with a radius end—provides exceptional versatility, allowing operators to machine contours, arcs, and confined spaces with the same tool used for surface leveling. This specific geometry is essential for mold and die making, as well as general fabrication tasks where accessing tight corners without gouging is critical.

One of the defining characteristics of Walter's carbide burr line is the meticulous attention to concentricity. Unlike inferior burrs that may wobble or vibrate at high RPMs, Walter burrs are precision-ground to ensure perfect balance. This reduction in vibration not only improves operator comfort and reduces fatigue but also significantly extends the life of the die grinder bearings and the burr itself. The stability provided by this balance allows for more controlled material removal, resulting in tighter tolerances and reduced rework time.

The "Double Cut" flute geometry features rows of cutting teeth cut in two intersecting directions. This design serves a dual purpose: it increases the rate of material removal by creating more cutting edges, and it breaks down chips into small, granular particles rather than long, sharp slivers. For the operator, this means a safer working environment and a smoother finish on the workpiece. The 01V039 is specifically optimized for use on ferrous metals, including carbon steel and stainless steel, making it an indispensable asset in welding shops, foundries, and maintenance departments requiring efficient weld leveling, deburring, and hole enlargement.

Designed for high-speed pneumatic and electric die grinders, this burr maintains its cutting edge even under high thermal loads. The tungsten carbide substrate provides superior hardness and heat resistance compared to high-speed steel (HSS) alternatives. Whether you are preparing a joint for welding, cleaning up a casting, or performing maintenance repairs, the Walter SC-2 Double Cut delivers consistent, aggressive performance without sacrificing surface quality.

| Additional Information |

|---|

| Packaging Description:1 per each |

| Brand:Walter |

| Used to Grind:Steel or Stainless |

| Shape Code:SC-2 |

| Cut Type:Double Cut |

| Material:Tungsten Carbide |

| Shape Description:Cylindrical Radius End |