Usually ships within 3-5 business days

The Walter SC-1 Double Cut Carbide Burr (01V005) represents the pinnacle of rotary file technology, designed for professional metalworkers who demand efficiency and precision. Crafted from the highest grade of tungsten carbide, this tool is engineered to withstand the extreme heat and stress of heavy-duty grinding applications. Unlike standard high-speed steel bits, Walter's carbide composition maintains its cutting edge significantly longer, ensuring consistent performance over an extended lifespan.

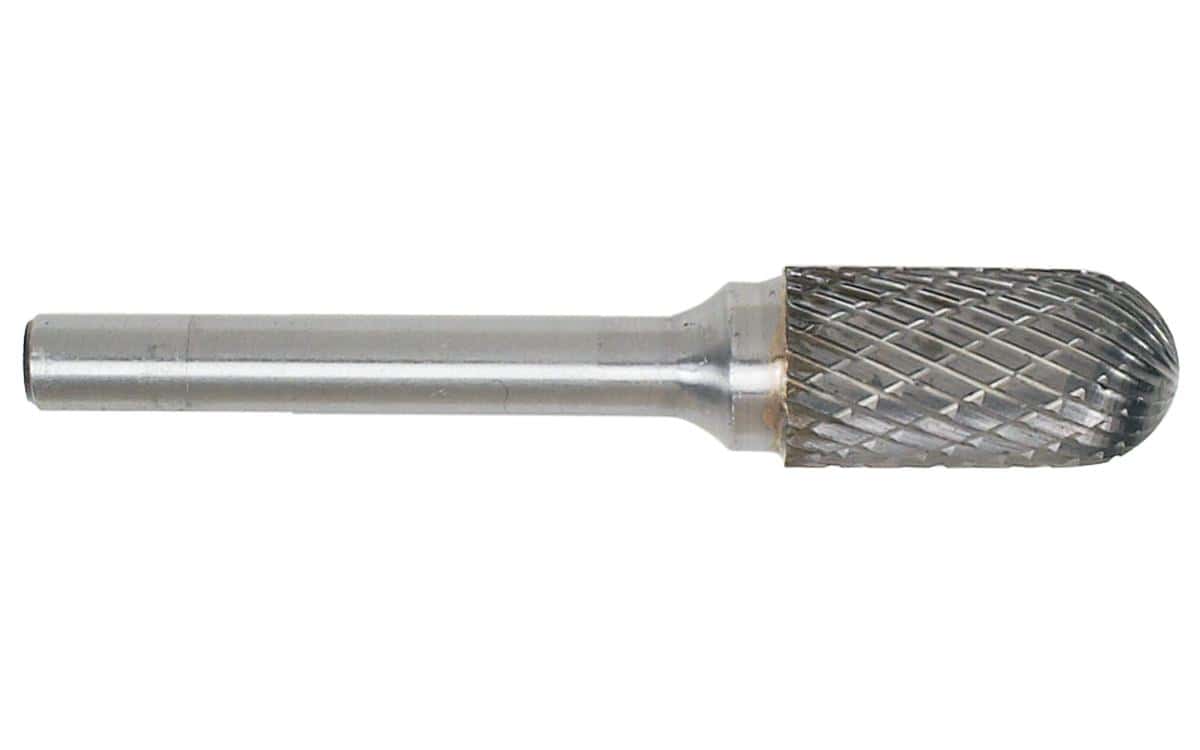

This specific model features the SC-1 shape, which is a cylindrical configuration with a radius end. This profile is exceptionally versatile, allowing operators to grind flat surfaces while also accessing corners and contoured fillets without digging into the workpiece. It is an essential tool for mold making, deburring castings, and smoothing weld seams in confined spaces.

The "DC" in the product name stands for Double Cut, referring to the advanced diamond-pattern fluting on the burr head. While single cut burrs are effective for general material removal, double cut burrs feature cross-cut flutes that break down chips into smaller, granular particles. This design offers several critical advantages:

One of the defining characteristics of Walter abrasives is their commitment to concentricity. This carbide burr is manufactured to exacting tolerances to ensure the head is perfectly aligned with the shank. This balance eliminates the vibration and chatter common in lower-quality bits, protecting both the die grinder bearings and the operator's hands from long-term stress. Whether you are enlarging holes, cleaning up welds on stainless steel, or performing fine finishing work, the Walter 01V005 delivers reliable, high-speed performance.

| Additional Information |

|---|

| Packaging Description:1 per each |

| Brand:Walter |

| Used to Grind:Steel or Stainless |

| Product Type:Carbide Burr |

| Shape:Cylindrical with Radius End (SC) |

| Cut Type:Double Cut |

| Material:Tungsten Carbide |

| Model:SC-1 |