Usually ships within 3-5 business days

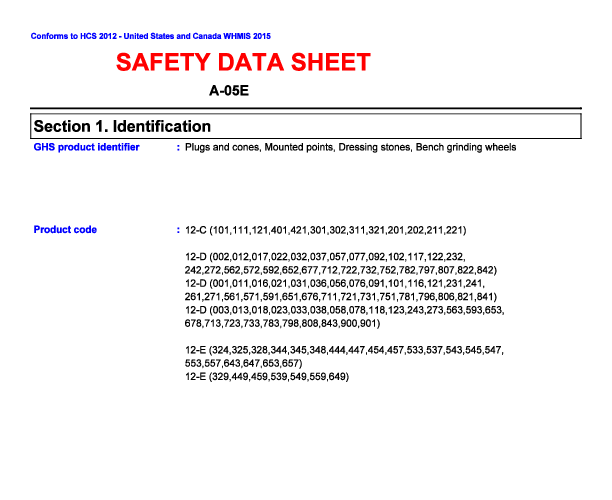

In precision industrial grinding, the condition of your abrasive wheel is just as critical as the machine itself. The Walter Dressing Stone (12D901) is a specialized maintenance tool designed to restore the cutting efficiency of diamond and Cubic Boron Nitride (CBN) grinding wheels. Over time, even the highest quality superabrasive wheels can become "glazed"—a condition where the abrasive grains are worn flat or the spaces between them become clogged with workpiece material. This leads to increased friction, heat generation, and poor surface finishes. The Walter Dressing Stone effectively cleans the wheel face, removing loaded material and eroding the bond matrix just enough to expose fresh, sharp abrasive crystals.

Regular maintenance with this dressing stone ensures that your expensive tooling investment continues to perform at peak levels. Unlike mechanical dressers used for standard vitrified wheels, this abrasive stick provides a gentle yet effective cleaning action suitable for the delicate matrices of diamond and CBN wheels. It is engineered to be soft enough to wear away during the process, providing a fresh slurry that aids in cleaning the wheel without dislodging the expensive superabrasive grains prematurely. Whether used in a tool and die shop, a sharpening service, or a heavy manufacturing environment, this accessory is indispensable for maintaining tight tolerances and high-quality finishes.

The 12D901 is formulated to bridge the gap between aggressive truing and light cleaning. It is particularly effective for off-hand dressing of bench grinder wheels or for use in precision setups where the wheel has lost its "bite." By regularly introducing the dressing stone to the wheel surface, operators can prevent the thermal damage associated with dull abrasives, ensuring that the temper of the workpiece is preserved. This stone is a compact, durable solution that belongs at every grinding station utilizing superabrasives.

| Additional Information |

|---|

| Packaging Description:1 per each |

| Product Type:Dressing Stone |

| Compatible Wheel Types:CBN, Conventional Abrasives, Diamond |

| Function:Cleaning, Deburring, Resharpening |

| Material:Aluminum Oxide |